Turnout / Signal Control using model aircraft servos

Revised 5 February 2023

Introduction

Model aircraft servos make excellent mechanisms for model points and semaphore signals. They have a high torque, a variable speed and endstop adjustment and consume virtually no current when stationary. Also they are available cheaply in small sizes and are adaptable for numerous mounting arrangements above or under the board. They do, however, need an electronic servo controller to supply the correct signals for servo control, which is where MERG comes in.

As well as points and signals members have also used Servos for other animations such as Level Crossing Gates or Barriers, Water Cranes, Shed doors, etc.

In summary, for operation of a point or signal three things are needed:

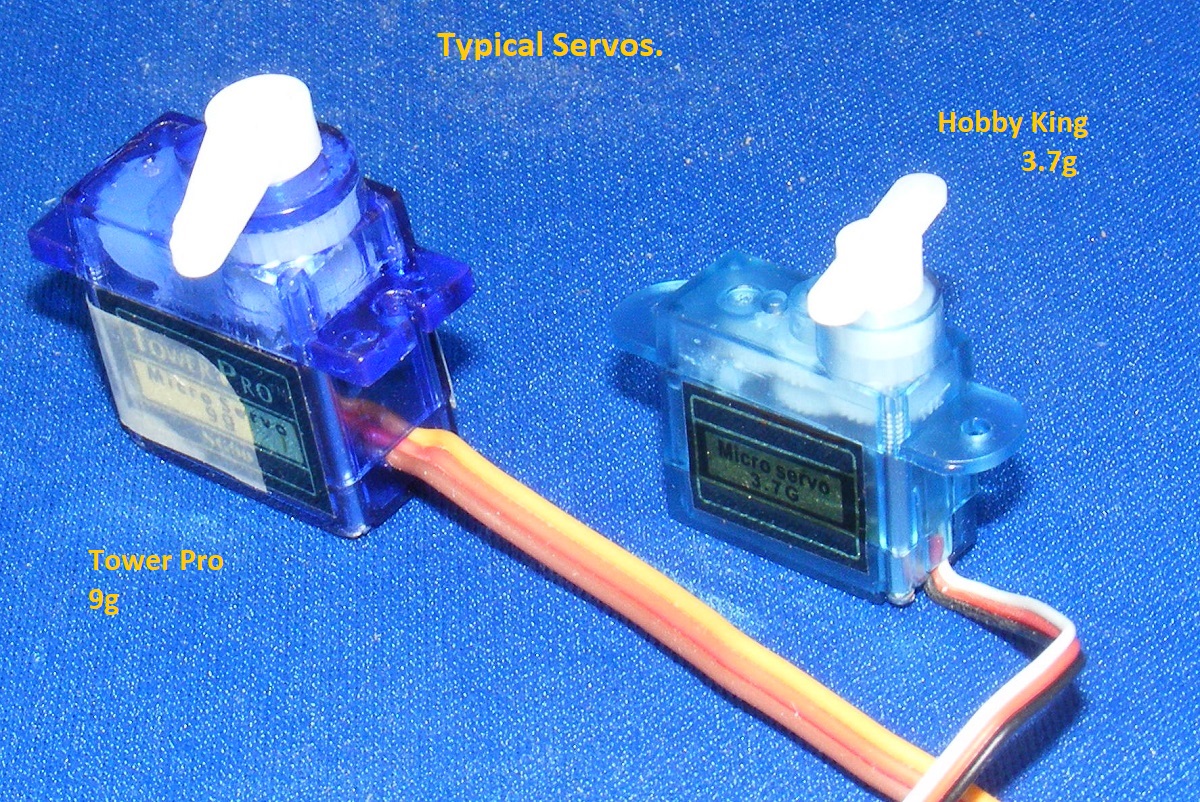

1. A servo motor, for example a Tower Pro SG90 or a Hobby King HK-15178

2. A servo mount and linkage, MERG offers a variety of 3D printed mounts in its kit range, alternative designs are available from members (Dingo mounts www.dingoservo.co.uk) or from commercial sources such as Model Signal Engineering (MSE http://www.modelsignals.com/sm_parts_frame.htm). Mounts are also easily made DIY.

3. An electronic servo driver, MERG offers a variety of kits capable of controlling up to 1, 4, or 8 servos. Ideally the driver board should be within 200 mm of the servos so that the leads will reach without need for extensions. This implies that boards driving multiple servos are better suited to N gauge than 0 gauge.

The cost per point, if using kits for the controllers and mounts, is usually significantly less than commercial point motors. With the flexible control features servos including full adjustable speed and throw servos are a very good choice for model railway controls.

Servo Motors

This image shows the most common servo size for Model Railway use, the 9g servo together with a smaller 3.7g servo. Even smaller versions are available (eg. HK-5320 Ultra-micro 1.7g). The small versions can be used for signals with DIY mounting arrangements. Most kit mounts are designed for the 9g servos which are ideal for points but have more torque than needed for signals.

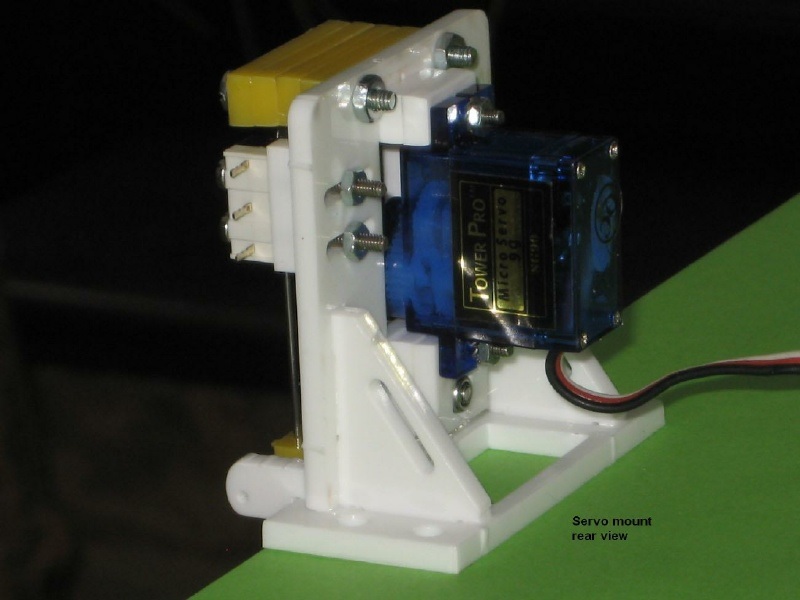

MERG Servo Mount Kit 681.

This is a 3D printed mount for 9g servos designed for point operation from under the board. It has facilities for addition of microswitches for control of crossing polarity or for position feedback.

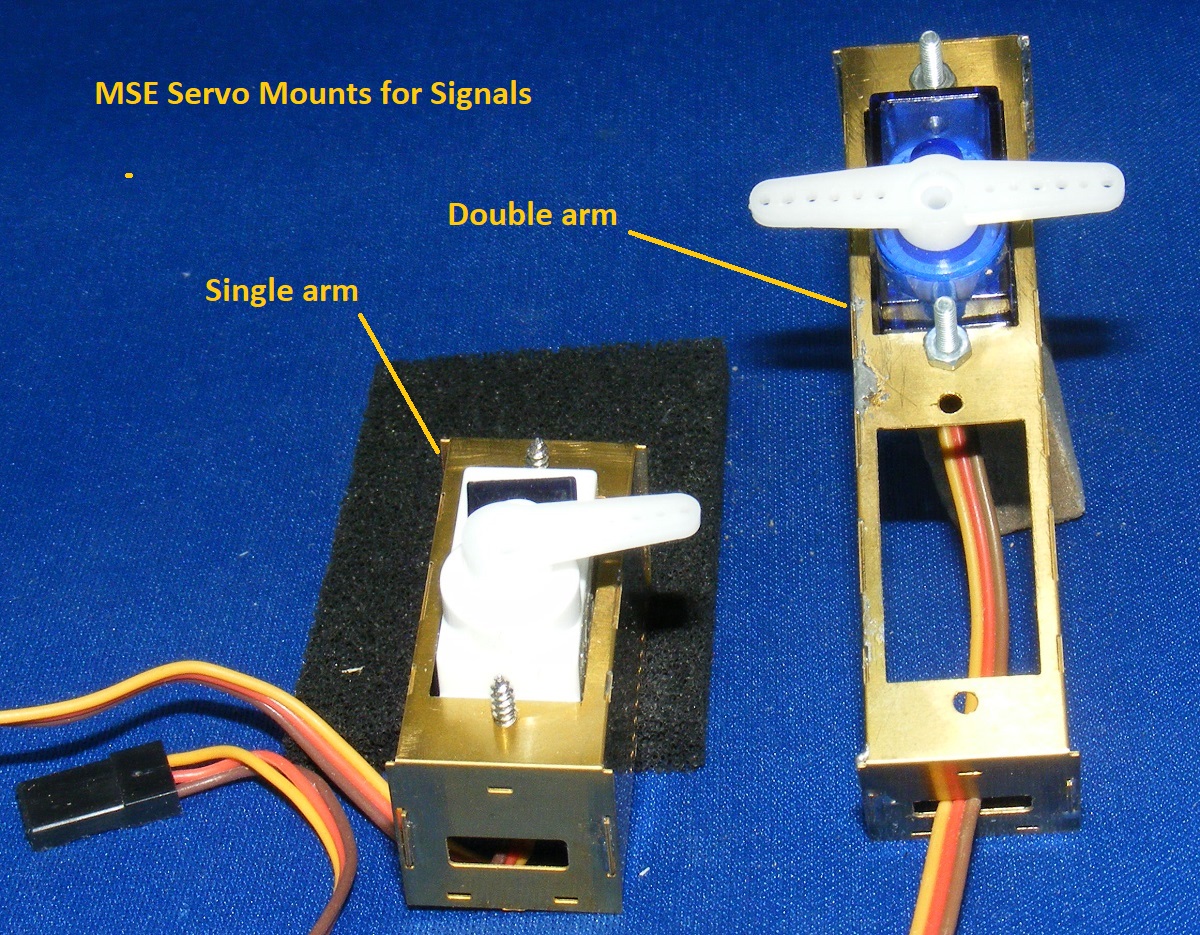

MSE Servo Mounts

These are servo mounts intended to fit to signal posts allowing the signal complete with servo to plug into a hole in the baseboard. The mounts are simple fold up brass etchings and come for one or two 9g servos.

Signal with MSE Mount

This illustrates the MSE mount assembled with a simple upper quadrant signal and a Tower Pro servo.

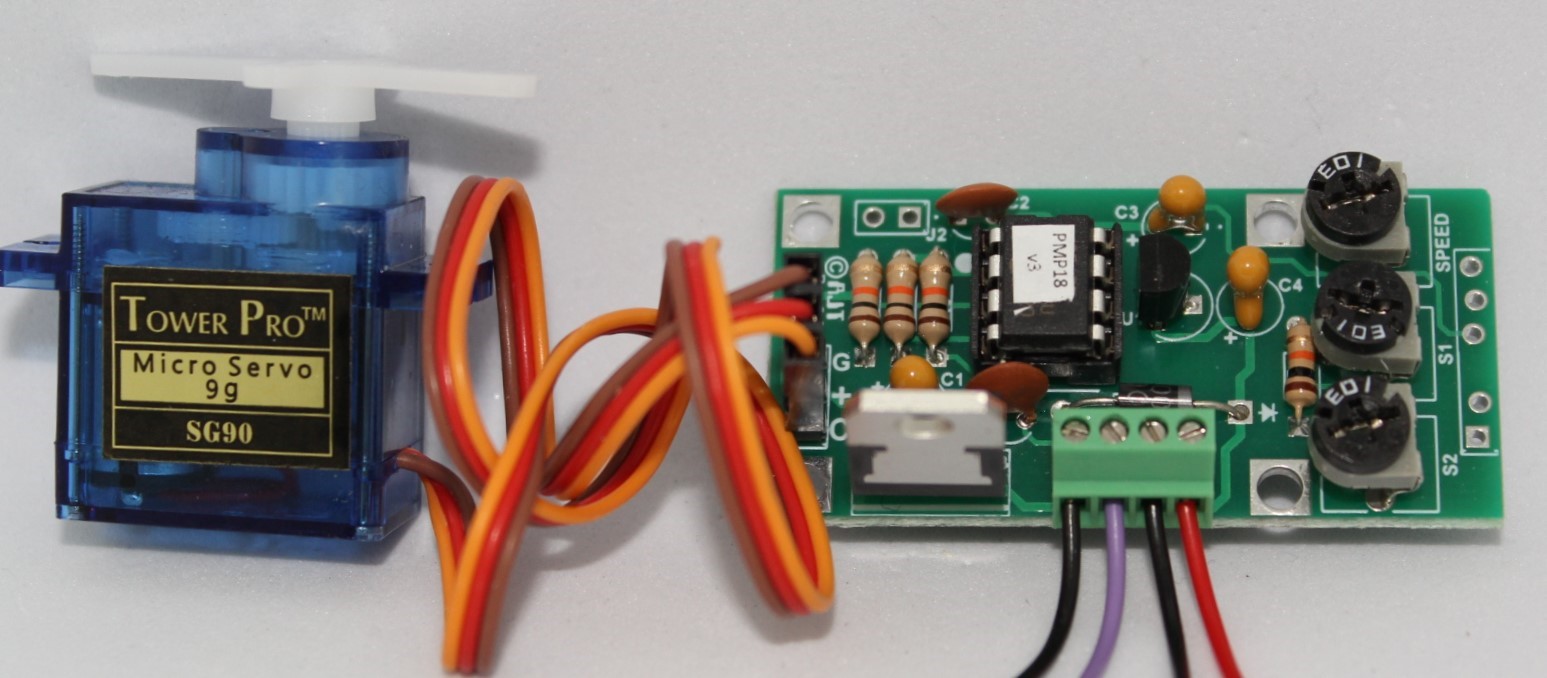

EzyPoints Kit PMK18

This shows the EzyPoints kit, for a single servo, built up on the PCB suplied. NB. Servo shown is not supplied with the kit.

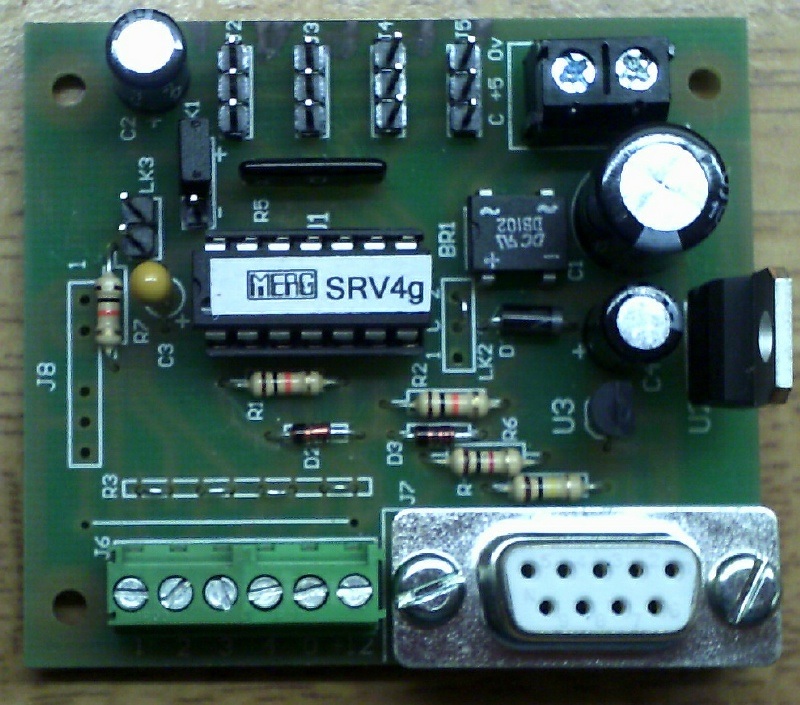

Servo4 Kit 75

This is the original and best selling MERG servo controller capable of controlling 4 servos.

Servoset Kit 76A

This shows the assembled Servoset2 kit, The setting box is used to set the end points and running speed for the 4 servos controlled by a Servo4. The kit includes the case and takes its power from the Servo4 so needing no seperate power supply. Note that the settings can be done from a PC with a basic USB-Serial adapter cable if prefered.

Videos

These Youtube videos from one of our members show typical applications of servos. All of these examples are controlled by a Servo4.

MERG Servo Controllers.

The first controller offered by MERG is the Servo4. This is a microprocessor controlled driver board designed to operate four separate conventional servo motors. Over the last 15 years thousands of these kits have been sold and it continues to be one of our most popular kits. The board has four standard servo connectors and provides the power supply and variable width pulses to operate the servos. Each servo has two presettable positions controlled by simple on/off switches or by a connection to a remote control output board. Not only can the positions be individually set but the rate of travel is adjustable with the choice of a different rate in each direction for each servo. Alternative software is also available to allow setting of 'bounce' for semaphore signals. The Servo4 board is setup using a serial cable from a dedicated setting box (also a kit) or from a computer using a small setup program.

The following downloads are available couresy of Mike Bolton, the Servo4 designer:

- zip file contains this description plus drawings, schematics, board layout and PIC code

- zip file contains the software for setting parameters from PC

Other alternative servo controller kits are:

For single servo drive: EzyPoints, kit 4818 in the Pocket Money Kits range, this is a simple kit with set up by variable resistors on the board to allow adjustment of both end positions and speed.

Also for a single servo: Servo1, kits 77 and 77R. A bit more sophisticated than Ezypoints, kit 77 comes with firmware able to provide for signal bounce while 77R includes a relay designed for frog switching at mid travel. These kits are set up using a simple setting box, kit 77S.

For eight servos the CANMIO, kit 98A, in the MERG CBUS range provides for remote control of 8 servos via the CBUS with setup from a PC.

Copyright

Copyright for items on this website is retained by the authors. Further licensing details are available on our copyright page.

The use or misuse for the sale, design, supply, process, installation, delivery, test, repair, servicing, and alteration of the designs, instructions, computer code, photographs, circuits, and any other information that appear on this web site is entirely at the risk of the user or visitor to the web site. The information is made available in good faith without warranty of any kind strictly on the basis that no liability will attach to the Model Electronic Railway Group (MERG), its officers and members.